-

Borgotaro

Factory

In the heart of Borgotaro, among the enchanting Parma hills, lies our factory, a place where tradition and innovation meet to give life to mosaics of extraordinary quality.

Here, far from the large industrial districts, ceramics take shape thanks to the experience and creativity of the people who live this territory, transforming the material into authentic works of art.

FROM EARTH TO MOSAIC:

TRADITIONAL TECHNIQUES

AND INNOVATION

In our factory, ceramics are conceived as an expression of a craft culture fine-tuned over time. Here, a mosaic is not a collection of tesserae, but a work that holds the mastery of those who made it. A story of earth, fire and passion that takes shape through expert hands.

From the selection of the raw materials to the processing, in each step of our production process the manual skill of our craftsmen is combined with the precision of new production techniques, giving life to surfaces that tell a story of a legacy of research, creativity and experience.

In the heart of Borgotaro, amidst the enchanting Parma hills, lies our factory, a place where tradition and innovation meet to give life to mosaics of extraordinary quality.

Here, far from the large industrial districts, ceramics take shape thanks to the experience and creativity of the people who live this territory, transforming the material into authentic works of art.

PROCESSING

STAGES

Our tiles are born from the perfect union of traditional craftsmanship and technological innovation.

Stage 1 – Pressing

Our processing begins with the pressing of earth and powdered glazes, combining high quality raw materials to create the perfect base for each mosaic. This stage ensures compactness and solidity, resulting in tesserae with unique colour depth, thanks to advanced double and triple loading technologies.

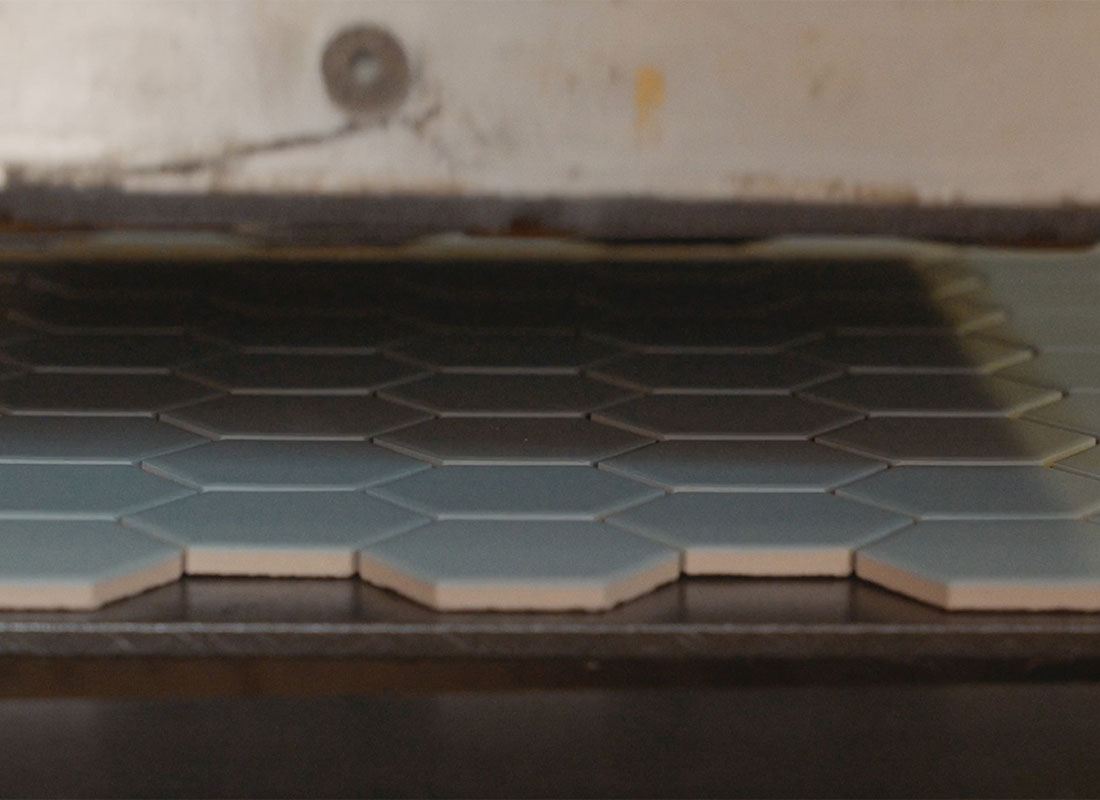

Stage 2 – Firing

After pressing, the tiles are fired in electric kilns powered by photovoltaic panels, which help reduce the environmental impact of the entire production process. The slow, controlled firing at high temperatures gives strength and colour stability, while maintaining the handcrafted quality of each piece.

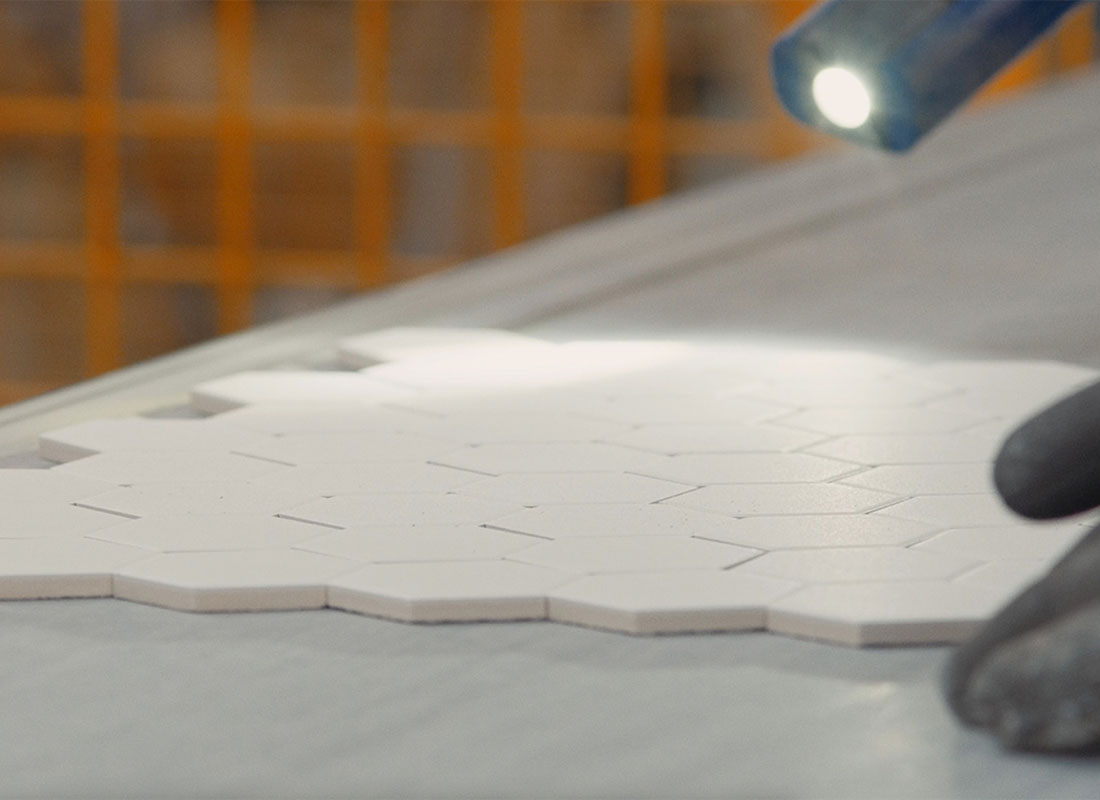

Stage 3 – Selection and quality control

Quality control takes place in three stages: inspection of the tiles for cracks or defects, precise positioning on the template for uniform assembly, and the final check of design, colour and strength. Only perfect mosaics reach our customers.

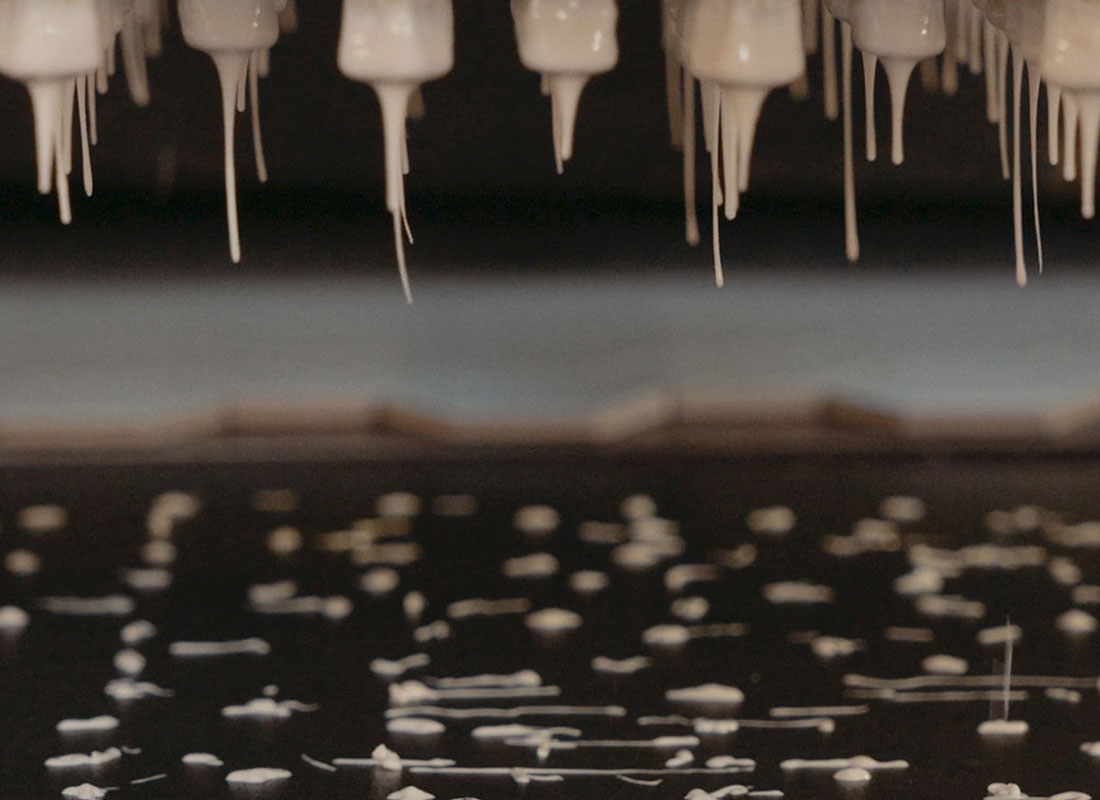

Stage 4 – Gluing

Each tile is carefully positioned and glued onto sheets using a unique glue-stitch method. This technique guarantees millimetric precision and stable assembly, while maintaining the harmony of the design. The glue used offers perfect adhesion, giving strength without compromising the flexibility of the installation.

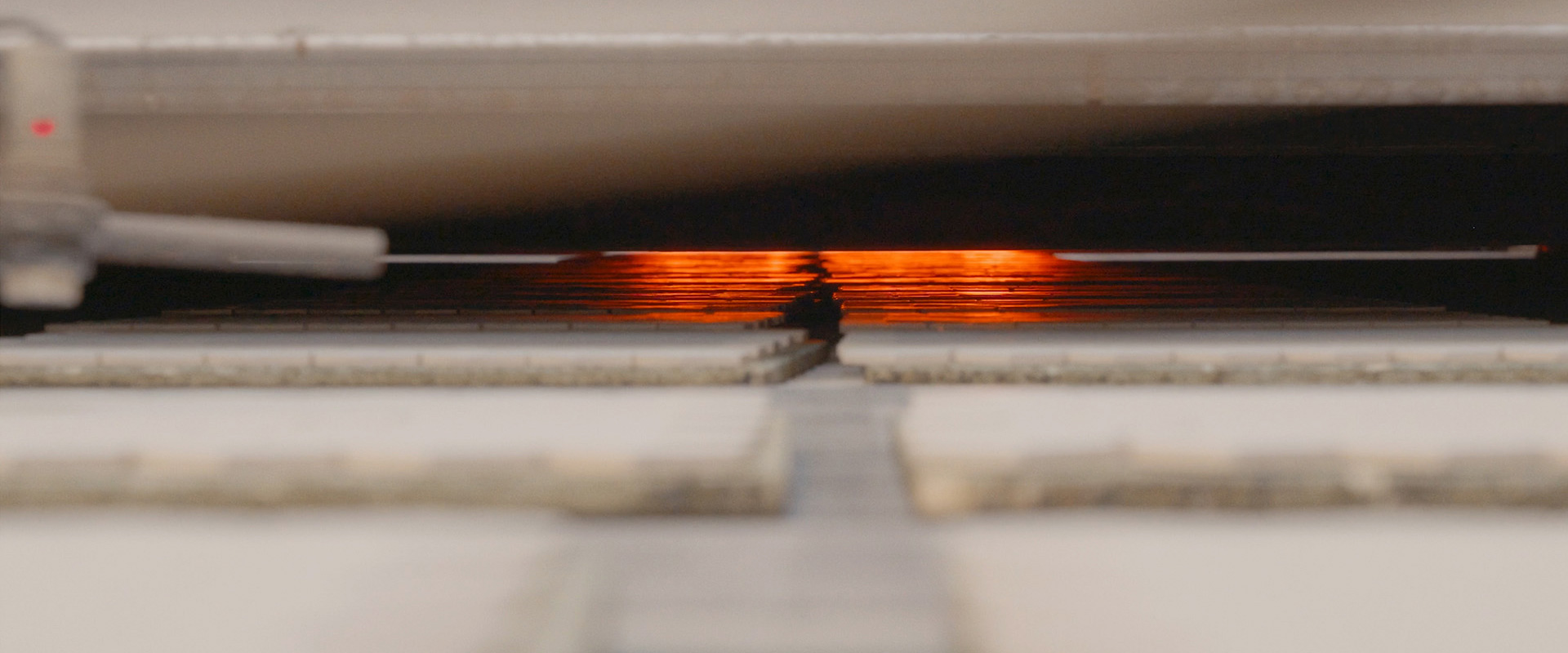

Stage 5 – Polymerization

After gluing, the sheets pass through a 130-degree oven to polymerise the glue. This heat treatment ensures a solid and durable bond, maintaining the structural integrity of the tiles and guaranteeing the stability of the mosaic over time.

Stage 6 – Automatic packaging

The last stage in the production process is automatic packaging, which protects each mosaic during transport and preserves its quality. We use state-of-the-art packaging systems to ensure safety, efficiency and sustainability in packaging and product handling.

THE PRODUCTS

Discover our products, the result of a timeless art that transforms ceramics into true works of art.

A SMALL GESTURE FOR SUSTAINABILITY

If you are not browsing or have stepped away from the computer, you consume less energy with this screen. To resume browsing, simply click anywhere on the screen.