-

Artigiana

Workshop

Our tiles are born from a passion for ceramic art, the result of research, inspiration and meticulous attention to detail. We have our roots in ancient craft techniques, reinterpreting them with a contemporary vision that combines the experience of the past with the creativity and tools of the present.

This balance has allowed us to reach new horizons in ceramics, enhancing the perfect union between tradition and innovation.

With Laboratorio Artigiana, we have chosen to invest in advanced technologies that respect the heritage of handmade ceramics, enriching it with new expressive possibilities.

We have gone beyond the idea of mass production to embrace a concept of artistic design, made up of unique pieces in which the craftsman’s hand conveys authenticity and value. Each creation thus becomes an exclusive work, a tribute to the timeless beauty of craftsmanship.

FROM THE HANDS TO

THE HEART: THE UNIQUE WORK

OF ARTIGIANA WORKSHOP

According to Walter Gropius, there is no substantial difference between artist and craftsman: both strive for perfection in their craft to bring their work to life. For Artigiana Workshop, each tile is a work born of hands, head and heart.

The production process is entirely artisanal: the dough loaves are cut, pressed and left to dry for a week. They are then baked for 18 hours in a traditional muffle oven at 1000 degrees.

After baking, each tile is glazed and checked in detail. This is followed by a second firing and further selection based on strict quality standards.

For Artigiana Workshop, craftsmanship is the ultimate expression of perfection.

PROCESSING

STAGES

Artigiana Workshop combines advanced technology and tradition of ceramic culture to create unique pieces, far removed from mass production. Each piece is the result of human effort: a celebration of the timeless beauty and authenticity that characterises craftsmanship.

Stage 1 – Wet pressing / Extrusion

The mix is carefully pressed to obtain the raw biscuit, the perfect base for each tile. This step ensures solidity and uniformity, preparing the surface for subsequent handcrafted treatments.

Stage 2 – Drying

After pressing, the tiles are left to dry for a week. This slow natural process eliminates residual moisture, preserving the integrity of the material and preventing deformation during firing.

Stage 3 – Filing

Each tile is finished by hand with careful craftsmanship. Filing removes any imperfections, ensuring defined edges and a uniform surface, enhancing the accuracy and quality of the handwork.

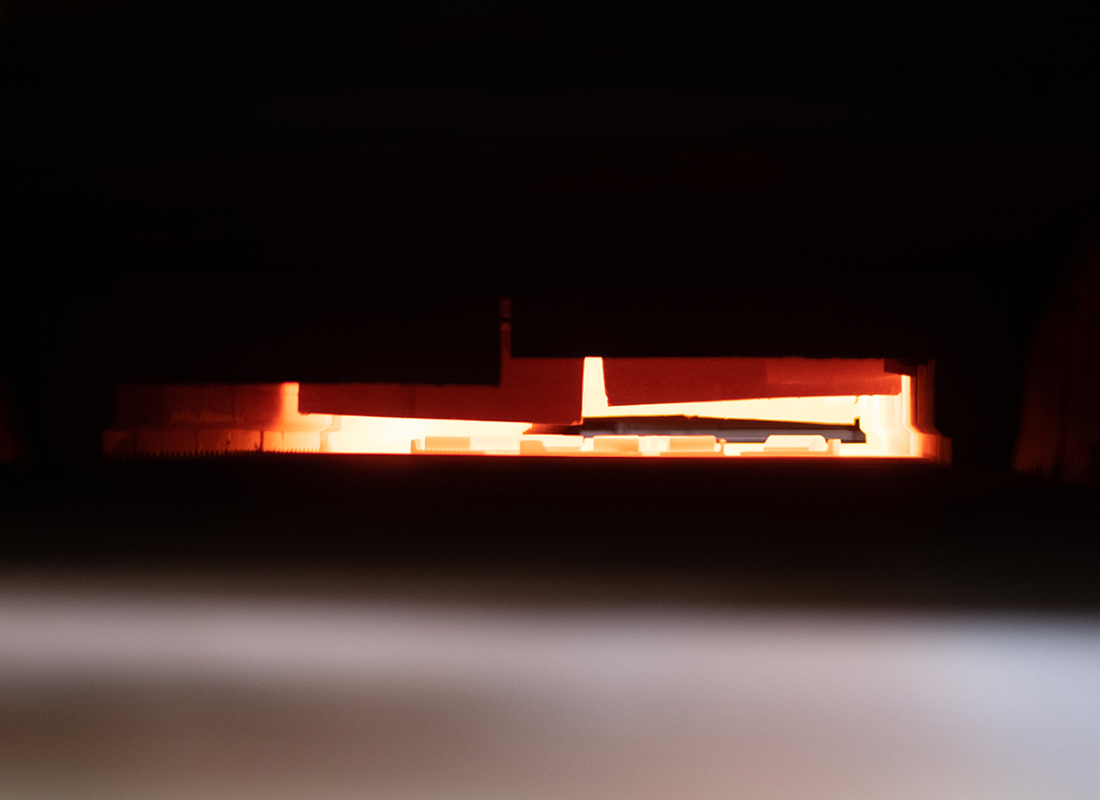

Stage 4 – Muffle kiln

The dried tiles are slowly fired in a traditional muffle kiln, reaching 1000 degrees for 18 hours. This slow firing gives strength and resistance, transforming the raw clay into a solid and durable base.

Stage 5 – Glazing

Each tile is individually glazed, with meticulous attention to detail. This step adds colour and finish, ensuring uniformity and aesthetic beauty, while maintaining the handcrafted uniqueness of each piece.

Stage 6 – Firing in a rapid kiln

After glazing, the tiles pass through a rapid kiln to permanently fix the colours and finishes. The finished product conforms to very high quality standards and at the same time reflects all the steps of craftsmanship it has undergone.

PRODUCTS

Discover our products, the result of a timeless art that transforms ceramics into true works of art.

A SMALL GESTURE FOR SUSTAINABILITY

If you are not browsing or have stepped away from the computer, you consume less energy with this screen. To resume browsing, simply click anywhere on the screen.